Currently there are no products in your shopping cart!

Fiberglass technology GRP

RELATED PRODUCTS

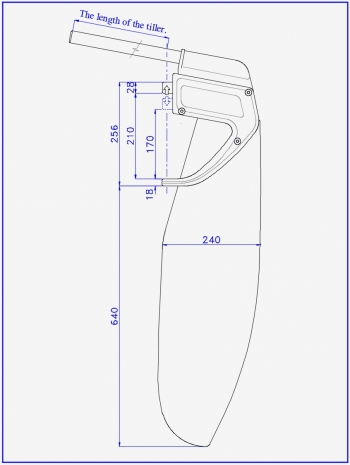

Advantages of the Dotan Rudder

Instant Rudder Control

The Dotan kick-up system allows the blade to be raised or lowered in seconds with a single movement. Essential for smooth departures and returns, even in challenging conditions.

Durable Housing

Made from corrosion-resistant composite materials, the rudder housing ensures reliability and stability, even in extreme situations.

Lightweight and Strong Blade

Combining advanced thermal shock technology and high pressure, the blade offers reduced weight and excellent durability. A hydrodynamic profile ensures smooth sailing.

Universal Adjustment

Easily adaptable to various boats and catamarans, the rudder’s simple installation makes it suitable for users of all experience levels.

Obstacle Protection

The blade automatically kicks up upon collision with obstacles like rocks or logs, preventing damage. It returns to position in seconds, maintaining control and stability.

Why Choose Kick-Up Rudders from Dotan?

Learn more about the Dotan rudder mechanism

SHOP NOW

DE

DE ES

ES IT

IT FR

FR RU

RU